Door Anatomy Guide

Core

The core of the door are the materials that make up the inside of the door panel. The core is completely dependent on the door type. Cores vary in materials as well as thicknesses, therefore providing different levels of insulation and support for the various door panels.

Wood Core

Moisture resistant, sustainable product used to provide durability and strength while resistant to moisture absorption. This product is formaldehyde-free and utilizes a high percentage of post-industrial wood fiber to manufacture.

Honeycomb Polymer Core

The honeycomb shapes of the expanded polyethylene provide a strong lightweight core with structural integrity. The strength of the design creates a door panel that is lightweight and able to accept the abuse of personnel, cart and pallet traffic.

Wood and Foam Core

The combination of composite wood and Urethane Foam provides a strong panel with the added benefit of an elevated R value. A good choice for cooler application openings between a conditioned and non-conditioned environment.

High Density, Foamed-In-Place, Non-CFC Urethane Core

Provides the highest R value door panel. The core of the panel is “foamed” (as a thick liquid) “in place” after the door panels are built. As the foam expands it fills the entire core leaving no gaps or crevasses, becoming a strong component of the door panel. The process provides excellent adherence of the foam core to the skins (decreasing risk of delamination).

Urethane Foam Core

Lightweight insulation sheet material provides strength and durability along with the desired insulation value for applications requiring/desiring an insulated core, such as cooler applications or an opening dividing a conditioned environment from a non-conditioned environment.

Back Channel

Back Channels, both internal and external, provide additional support and ensure panel rigidity. Depending on the particular door, back channels are constructed of a heavy-duty aluminum with a powder coat finish, as an internal reinforcement with tubular steel, a galvanized steel with powder coated satin black, or stainless steel.

Vision Panels / Windows

There are many different Window / Vision Panel variations offered based on the door selection. Larger Windows are in some cases preferred or required due to heavier traffic, specifically motorized, within certain installations; and in other cases, a standard window is perfectly suitable for the application.

Depending on the Door selected, our windows are offered as scratch-resistant acrylic set in rubber molding, scratch-resistant double pane acrylic, scratch-resistant recessed polycarbonate with Aluminum frame, or scratch-resistant triple pane recessed polycarbonate with black ABS frame.

Size options vary depending on door selection.

Hinges

Hinges play a key role in the performance of a door and vary depending on the door type and construction. Hinges offered range from our Gravity Hinge System, V-Cam Hardware Systems, Spring Hinge System and Breakaway Hinges. Hinges are based on the door selection.

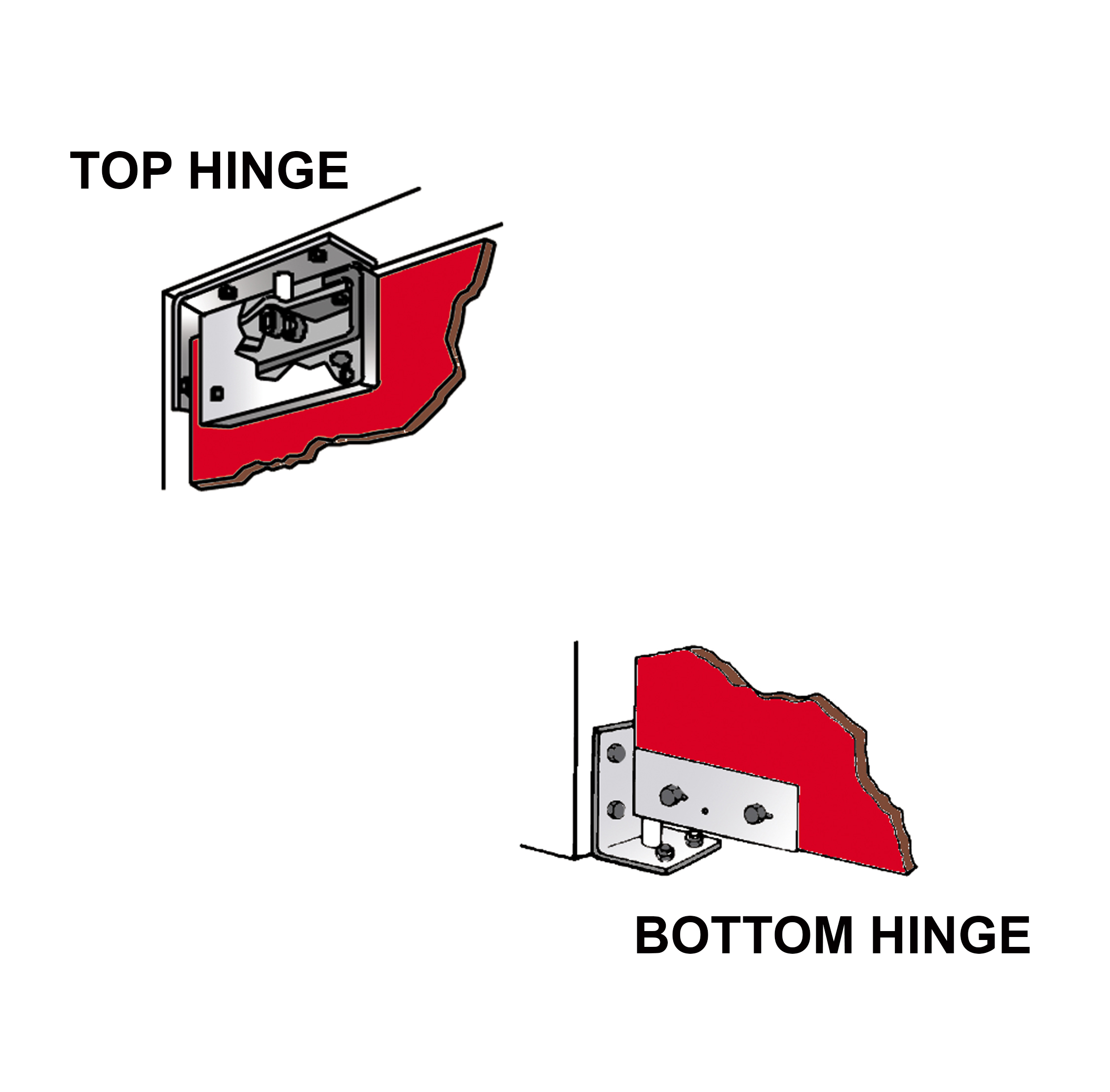

Gravity Hinge System

If ease-of-access along with quick and easy installation is what you desire, the Gravity Hinge System ranks at the top. The top-mounted, hardened steel cam plate and rollers are accompanied with a steel bottom pivot pin, allowing the door to open and close with minimal impact (requires less than five pounds of force to open the door, always ADA Compliant). The Gravity Hinge System allows the door to easily open on impact and closes automatically, has smooth and quiet operation, and reduces impact damage to the door panel.

V-Cam Hardware Systems

V-Cam Hinges are designed to withstand highly abusive traffic, specifically forklift, and also offer greater resistance to wind pressure. The Upper V-Cam casting is ductile iron or stainless steel and includes a ramp, available in low or standard rise configurations. The roller assembly attaches to the upper hinge post and the door rises when opening, as the roller travels up the ramp in the V-Cam.

Spring Hinge System & Bottom Breakaway Hinges

Our Spring Hinge System is featured on our Flexible Door Products, and in some cases with certain models, it is paired with our Bottom Breakaway Hinges. The Spring Hinge System is constructed with a spring return, allowing the door to swing on an even plane. The swinging arms and mounting brackets are a heavy-duty galvanized steel, located at the top of the door only – away from common traffic patterns.

When Breakaway Hinges are present, they are located towards the mid to bottom of the door panels on each side, allowing the door to “break away” and dislocate from the Hinge, in order to accommodate for wide traffic loads.

Jamb Guard

A Jamb Guard is an additional protection feature, preventing horizontal movement of the door panels as well as protecting the lower hinge post from impact damage.

Gasketing

Our perimeter edge gasketing provides better sealing, longevity and reduced drag compared to others on the market. The two-ply, reinforced blade gasket makes pulling or pushing on the panel when operating the door no longer necessary to achieve a tight seal.

Impact Plates / Bumpers

Impact Plates and Bumpers are added towards the mid to bottom of specific doors for additional support, where heavy wear and tear is commonly seen from high volume, heavy duty traffic.

Depending on the door selected and the options available, Impact Plates provide an additional “layer” to the door surface, available in stainless steel and an array of sizes.

Bumpers, which actually sit partially off of the door panel, provide spring action, impact absorption and protection from heavy traffic loads that pass through the door opening. Bumpers are commonly seen in high traffic, heavy duty applications.